Innovations and new developments

Our service spectrum

Innovations and new developments

Boring-enabled steel sleeve pipe

(DMI patent no. 10 2008 005 452)

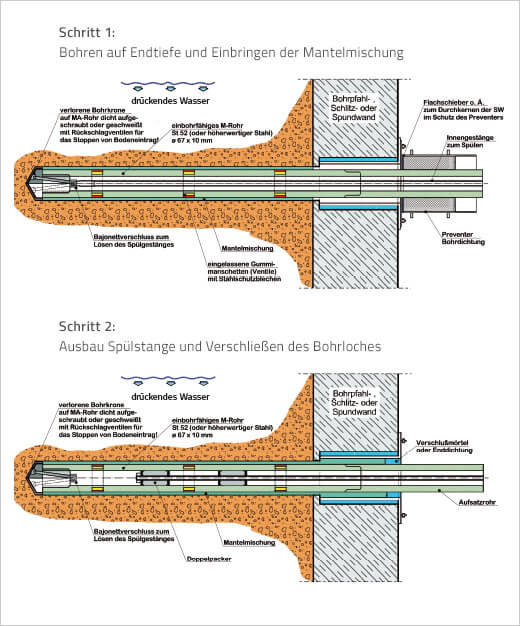

Subsidence often takes place due to ground extraction when producing boreholes for sleeve pipe injections, especially in the vicinity of groundwater and underneath buildings. DMI has developed a unique boring system for this eventuality with which it is possible to drill in the sleeve pipes directly without protective casing.

Around five to six work steps are normal for drilling procedures in accordance with the current state of the art. The DMI system requires just two work steps and it can be deployed in small spaces. The engineering office CDM Consulting Berlin evaluated the drilling procedure and injection on the basis of a test boring operation and compiled a positive report on it.

Benefit: Two work steps

Pipe shields with boring-enabled sleeve pipe

The current state of the art for pipe shields does not professionally allow for one-off or repeated grouting via the driven-in valves. The valves fall out during drilling in or do not close properly.

DMI has found a unique solution for this and further developed the patented DMI steel sleeve pipe for pipe shields that allow for repeated grouting.

- Drilling in (drawing in) the pipes with drilling jumbo by excavation personnel

- No ramps for anchor drill necessary

- Repeated grouting possible

- Post-grouting possible for sealing purposes, even after excavation ø 76.1 / 88.9 / 101.6 / 114

Boring-enabled sleeve pipe for pipe shield

Ring drill bit with latched pilot bit